Anodizing Finishing Services

Anodizing electrolytically creates a durable oxide layer on aluminum for superior protection and aesthetics.

By passing an electric current through an electrolytic bath, a tough oxide layer forms that resists wear and corrosion while accepting color dyes for vibrant, long-lasting finishes.

The resulting anodized surface offers enhanced durability, insulation, and visual appeal. This makes anodizing a popular technique to extend product life, improve performance, and achieve a polished look across industries.

Anodizing Overview and Advantages

Anodizing electrolytically creates a durable oxide layer on aluminum for superior protection and aesthetics.

By passing an electric current through an electrolytic bath, a tough oxide layer forms that resists wear and corrosion while accepting color dyes for vibrant, long-lasting finishes.

The resulting anodized surface offers enhanced durability, insulation, and visual appeal. This makes anodizing a popular technique to extend product life, improve performance, and achieve a polished look across industries.

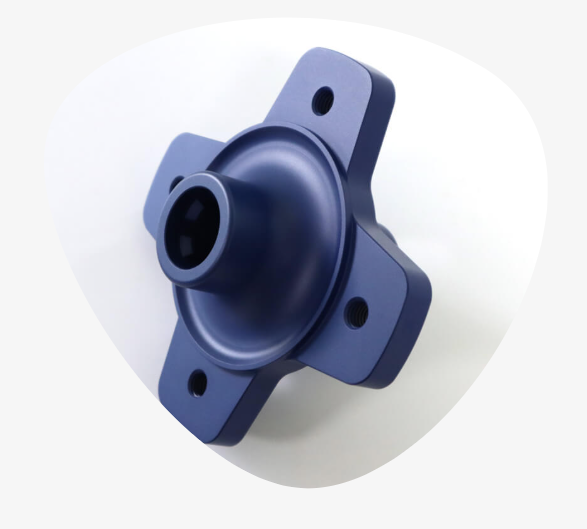

Enhanced Durability

Anodizing creates a thick oxide layer on the aluminum surface. This layer, being much harder than the aluminum itself, offers enhanced protection against chipping, peeling, and scratching, ensuring the component's longevity

Corrosion Resistance

The protective oxide layer formed during the anodizing process acts as a barrier against environmental factors such as moisture, salts, or other corrosive agents. This protection ensures that aluminum parts remain unaffected by rust or corrosion, especially in challenging conditions.

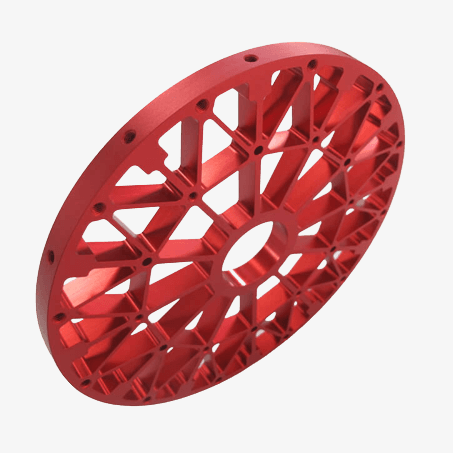

Improved Aesthetics

Anodized aluminum surfaces can be dyed in a variety of colors. This flexibility in design choices, coupled with a rich metallic sheen, often results in a more attractive appearance than untreated or painted surfaces.

Electrical Insulation

The oxide layer that results from anodizing acts as an insulator. This insulation property can be crucial in electronic applications where specific components must be electrically non-conductive to function correctly

Thermal Resistance

Certain types of anodizing can enhance the aluminum's thermal insulation properties, making it ideal for applications where heat retention or dissipation is a factor.

Improved Lubrication

Certain types of anodizing, like Teflon-impregnated hardcoat anodizing, can improve the lubrication properties of aluminum parts, reducing friction in moving components.

Types of Anodizing Offered by PY Precision

Anodizing type II (Matte)

Anodizing Type II, often referred to as “Matte,” is a sulfuric acid anodizing process. It produces a uniform, oxide layer on aluminum, ensuring enhanced corrosion resistance and a non-reflective, matte finish. This method allows for diverse color dyeing options, providing both protection and aesthetics.

Anodizing Type II film thickness is 8-12 μm (clear) or 12-16 μm (black/color)

| Color | Clear, black, blue, red, gold or any RAL code or Pantone number |

| Material | Aluminum |

Noted: The dimensional accuracy achieved with various surface preparations is maintained after the anodizing process

Anodizing Type II (Glossy)

Anodizing Type II (Glossy) is a variant of the standard sulfuric acid anodizing process. It imparts a thicker oxide layer on aluminum, ensuring robust protection. Its unique procedure results in a reflective, glossy finish, elevating the part’s aesthetic appeal while maintaining its enhanced durability.

Anodizing Type II film thickness is 8-12 μm (clear) or 12-16 μm. (black/color).

| Color | Clear, black, blue, red, gold or any RAL code or Pantone number |

| Texture | Grit #120 |

| Material | Aluminum |

图片居左,文字在右边,自动上下居中

图片不要直接删除,可以点击修改

图片建议尺寸:600*400px

Anodized type III (Hardcoat)

Anodized Type III, known as “Hardcoat,” uses sulfuric acid to create a densely packed oxide layer on aluminum. This process results in enhanced wear resistance and electrical insulation. The thick, durable finish, often darker in hue, stands up to extreme environments and rigorous use.

Anodizing Type III film thickness is 25-50 μm.

| Color | Nature, black or other colors |

| Texture | Grit #120 |

| Material | Aluminum |

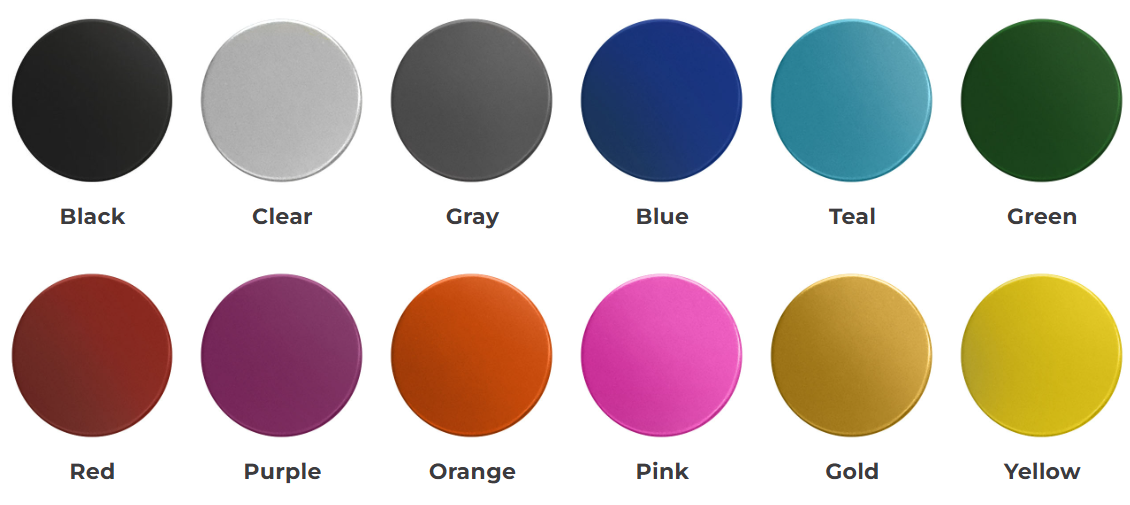

Custom Color and Thickness Options

We offer a selection of standard anodized color finishes (see Color Options). For custom RAL or Pantone color matching, contact our team at kate@khled.com to discuss your project’s requirements

Our standard anodized layer thicknesses conform to ISO 7599: ISO class AA10 for clear anodizing and ISO class AA15 for colored anodizing. Our experts can accommodate custom thicknesses if your application calls for alternative anodizing thickness standards. Reach out to kate@khled.com to request a quote for non-standard anodizing

Color options for aluminum anodizing

Because aluminum alloys have inherent variances, the final color of anodized parts may differ slightly from the standard color shades shown below. The color range indicates the spectrum of hues that can be expected with colored anodizing. Minor variations in hue are normal due to the tolerances in alloy composition.

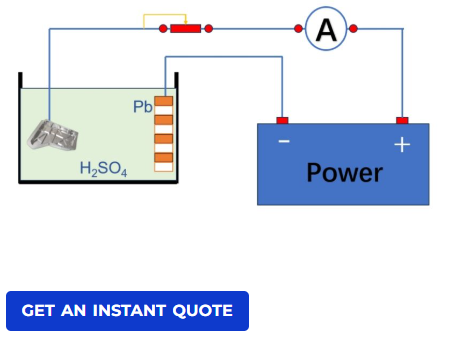

Anodizing process

Cleaning: Parts are cleaned in a non-etching, alkaline solution to remove surface impurities, ensuring a flawless anodizing result.

Rinsing: Cleaned parts are thoroughly rinsed with deionized water to remove any remaining cleaning agent residues.

Etching: Immersed in an acid bath (usually caustic soda), parts undergo etching to achieve a matte appearance or to prepare for further processing.

Desmutting: This neutralizes and removes surface contaminants, ensuring a pure aluminum surface for the subsequent anodizing process.

Anodizing: Parts are submerged in an electrolytic solution, typically sulfuric acid, and electrical current is passed to form the protective oxide layer.

Coloring (optional): After anodizing, parts can be dyed by immersing them in a bath containing organic or inorganic colorants.

Sealing: The anodized surface is sealed, typically in a hot water bath, to close pores, enhancing corrosion resistance and color retention.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899