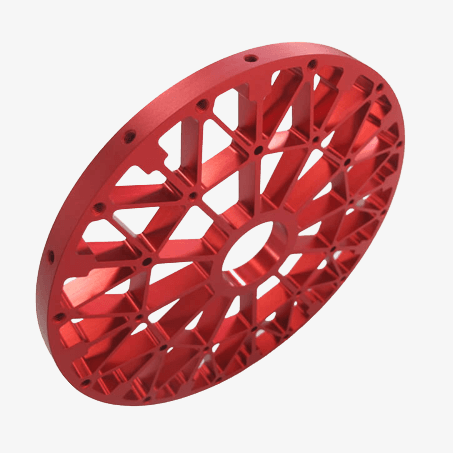

Carburizing Heat Treatment

Carburizing heat treatment infuses carbon into steel or iron surfaces at high temperatures, enhancing hardness and wear resistance while maintaining a tough, ductile core

How Steel and Iron Carburizing Works

Carburizing is a heat treatment process used to enhance the surface hardness of steel and iron components. The process begins by heating the metal to a high temperature, typically between 850°C and 950°C, in a carbon-rich environment.

This environment can be created using gas, liquid, or solid carbon sources. As the metal is heated, carbon atoms diffuse into the surface, increasing its carbon content.

After sufficient carbon penetration, the component is rapidly cooled or quenched, locking the carbon in place and creating a hard, wear-resistant outer layer while maintaining a tough, ductile core.

This dual-phase structure improves durability and performance.Important Details to Get Perfect Carburized Parts

The six most important details to pay attention to during the carburizing process, which can significantly impact the final result.

Temperature Control

Carbon Potential

Time Duration

Material Composition

Quenching Method

The cooling rate after carburizing impacts the hardness and microstructure of the case. Proper quenching media (oil, water, or air) should be selected based on the desired properties.

Atmosphere Control

Application of Carburized Parts

Other Finishing Services Available

Rust Our One-Stop Finishing Excellence

PY-precision’s industry-leading expertise ensures unrivaled quality and convenience with our comprehensive, one-stop finishing services.

APowder coating is a dry finishing process, using finely ground particles of pigment and resin electrostatically charged and sprayed onto surfaces. Cured under heat, it creates a durable, uniform, and attractive finish, popular for its environmental and performance benefits.QAluminum AnodizingA

Anodizing type II (Glossy)

Anodizing type II (Matte)

Anodizing Type III Har coat

A

Copper Plating

Electroless Nickel

Nickel Plating

Nickel Sulfamate

Tin Plating

Zinc Plating

A

Mechanical Polishing

Electropolishing

Vibratory Polishing

Mirror Polishing

QBead BlastingA

Glass Bead Blasting

Ceramic Bead Blasting

Plastic Bead Blasting

Steel Shot Blasting

Stainless Steel Bead Blasting

QBlack OxideABlack oxide, a conversion coating in surface finishing, chemically forms a protective black layer on metals, primarily ferrous alloys. It enhances corrosion resistance, reduces light reflection, and adds decorative appeal. Applied through hot or cold processes, the finish is often sealed with wax or oil to boost durability and protection.AChromate conversion coating, often known as Alodine or Chemfilm, is a surface treatment for aluminum and its alloys. It forms a thin, protective chromate layer, enhancing corrosion resistance, promoting paint adhesion, and providing electrical conductivity. Commonly used in aerospace and automotive industries, it offers a decorative finish with minimal dimensional change.ADLC (Diamond-Like Carbon) coating is a nanocomposite finish that imparts a hard, wear-resistant surface to materials. Mimicking properties of natural diamond, it offers exceptional lubricity, corrosion resistance, and a reduced friction coefficient, making it ideal for automotive, tools, and precision components.ABrushing in surface finishing uses abrasive brushes to create fine, consistent lines on metal surfaces. This mechanical process enhances appearance, masks defects, and prepares surfaces for coatings. Offering various textures, from short to long grains, brushing ensures aesthetic refinement for various applications.QTitanium AnodizingATitanium anodizing is a surface finishing process that modifies the oxide layer on titanium components. Enhancing corrosion resistance and biocompatibility, it also adds vibrant, interference-based colors without dyes or pigments. Popular in medical devices and aerospace, it combines aesthetics with functional benefits.QPassivationAPassivation is a surface finishing process that treats stainless steel with a mild oxidant, removing iron contaminants and enhancing its natural oxide layer. This strengthens corrosion resistance and prevents unwanted reactions in environments like the medical, food, and aerospace industries.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899