CNC Turning Service

China high-quality precision CNC turning services you can trust. Competitive pricing and fast lead times.

Over 50 Certified Materials

±0.005mm Tight Tolerance

Custom Finishes

Lead times from 7 days

Expert CNC Turning Services From China

Are you looking for a reliable, quick-turn supplier of CNC-turned parts?

PY-precision is a leading manufacturer of CNC-turned parts delivering excellent quality flexibly. Our highly skilled engineers, designers, and procurement teams ensure our services are provided on time and within budget. Our state-of-the-art CNC turning centers & lathes, combined with various finishing options, make us the perfect choice for your precision manufacturing requirements, from prototyping to production runs.

Why Order CNC Turned Parts From Us

Rapid Turnaround

We’re committed to reducing friction at every stage, so you can be as delighted with the speed of your CNC Turned parts’ arrival as you are with their exceptional quality. Order now to receive your parts in as little as 5 days!

A Wide Variety Of Materials

We offer over 60 production-grade materials including metal, plastic, and ceramic, and take great care to ensure the right material is used for every part.

High Accuracy

Our standard CNC tolerance is +/- 0.127mm, and when you use our tolerance configurator, you can expect precision machining to be +/- 0.005mm.

Perfect Finish

We offer high-quality finishing processes for most CNC Turned parts; including anodizing, polishing and plating, heat treatment, powder coating, and more.

Our Maximum capabilities for CNC turning

| Part size limitations | Metric units | Imperial units |

| Maximum part diameter | 508 mm | 20 inch |

| Maximum part length | 1066.8 mm | 42 inch |

| Maximum swing over the carriage | 355.6 mm | 14 inch |

| Maximum spindle through-hole | 50.8 mm | 2 inch |

CNC Turning General Tolearances

From intricate medical and aerospace designs to complex industrial parts, our ISO 9001-certified company creates precision components with the highest level of accuracy.

We utilize CNC turning lathes for complex machining projects requiring tight tolerance specifications up to ±0.005” – as close as a few thousandths of an inch!

Our standards for metals follow ISO 2768-m while plastics adhere to requirements set by ISO 2768-c.

| Type | Tolerance |

| Linear Dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole Diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft Diameters | +/- 0.025 mm +/- 0.001 inch |

| Part Size Limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

CNC Turning Design Guidelines

Our CNC machining experts have carefully compiled the ideal characteristics for creating precision components.

This table shows what works best, and also presents any technical limits to keep in mind during production.

| Feature | Recommended Size | Feasible size |

| Min. Feature Size | Ø 2.5 mm | Ø 0.5 mm |

| Internal Edges | R 8 mm | R 0.25 mm |

| Minimum Wall Thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter:standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 mm Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |

Materials For CNC Machining Parts

We offers a wide variety of materials for custom CNC machining, plastic, and metal, including but not limited to:

| Materil | Photo | Alloys: | Finishing Options: |

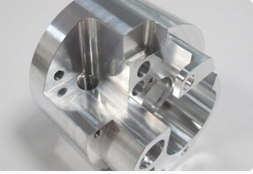

| Aluminum |  | 6061-T6, 7075-T6, 2024, 5052, 6060, 5083, 2017, 6082 | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing |

| Stainless Steel |  | SS303, Stainless Steel 304/304L, Stainless Steel 316/316L, Stainless Steel 17-4, Stainless Steel 416, etc. | As machined, Bead Blasted, Polishing, Decorative Chrome Plating, Powder Coat, Nickel Plating, Gold Plating, Silver Plating |

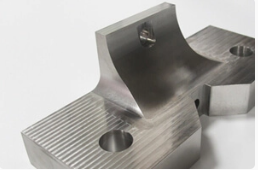

| Alloy Steel |  | AISI 1215, AISI 4140, AISI 4340, AISI 8620, AISI 4130 | Polishing, Plating, Painting, Powder Coating and etc. |

| Tool Steel |  | A2 Tool Steel, D2 Tool Steel, O1 Tool Steel, S7 Tool Steel, M2 Tool Steel | Bead/Sand Blast, Polishing, Plating, Painting, Powder Coating, Heat Treatment and etc. |

| Brass |  | C360, C260 | Nickel Plating, Bead Blasted, Gold Plating, Silver Plating |

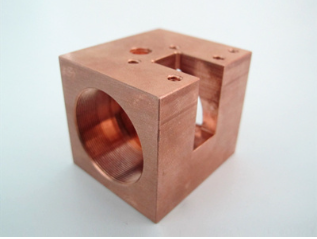

| Copper |  | C10100, C11000, C12200, C14500, C17200 | Plating, Polishing |

| Titanium |  | Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-2.5V | Polishing, Anodizing, Sandblasting, Chemical etching, Laser engraving and etc |

CNC Plastics

| Material | Photo | Color | Grade |

| POM (Delrin/Acetal) |  | White, black, brown | POM-C, POM-H, UV stabilized POM, Food-Grade POM |

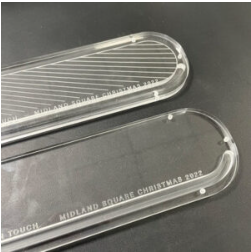

| PMMA (Acrylic) |  | Transparency | Extruded PMMA, Cast PMMA, Impact-Modified PMMA, UV-Stabilized PMMA, Heat-Resistant PMMA |

| PEEK |  | Beige with no transparency | Unfilled PEEK, 30% glass-fiber reinforced PEEK, 30% carbon-fiber-reinforced PEEK, Bearing Grade PEEK |

| ABS |  | ABS is naturally opaque and comes in a range of colors including black, white, and gray | General purpose ABS, Flame retardant ABS, High impact ABS, Heat-resistant ABS |

| Nylon (PA) |  | Nylon is often used in its natural off-white or slightly yellowish color | Nylon 6, Nylon 6/6, Nylon 11, Nylon 12 |

| PTFE (Teflon) |  | The color of PTFE is typically white or off-white | |

| PVC |  | clear or opaque | UPVC, PPVC, CPVC |

| PEI (Ultem) |  | Amber or brownish color | Unfilled PEI, Glass-Filled PEI, Carbon-Filled PEI, Ultem PEI |

Surface Finishes for CNC Machined Parts

We offers a wide selection of surface finishes to improve the surface qualities of CNC-turned parts.

The surface finishes applied after machining can change the appearance, surface roughness, hardness, and chemical resistance of the produced parts.

As machined (Ra 3.2μm / Ra 126μin)

This finishing option with the shortest turnaround time. Parts have visible tool marks and potentially sharp edges and burrs, which can be removed upon request

Smooth machining (Ra 1.6μm / Ra 63μin)

Smooth machining is similar to a ‘As machined’ finish, but with less visible machine marks. Parts are machined at a lower feed rate, with no hand polishing.

Polishing (Ra 0.8μm / Ra 32μin or better)

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment.

Bead Blasting

Machined parts are bead blasted with glass beads which results in a uniform grainy texture and reduced machining marks.

Tumbled

It is a process that tumbles vibrating media on machined parts to remove sharp edges and burrs.

Tumbling can be used to remove machine marks from exterior surfaces

.

Bead blasted + Anodizing type II

The parts are bead blasted to #120 grit before being anodized type II—ideal for increasing the aluminum part’s corrosion resistance and cosmetic effects.

Bead blasted + Anodized type III (Hardcoat)

The parts are bead blasted to #120 grit before being anodized type III. Type III (Hard Coat) is thicker and adds a wear-resistant layer to Type II’s corrosion resistance, suitable for functional applications.

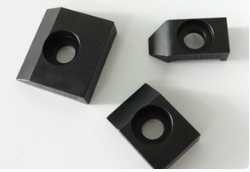

Black Oxide

Black oxide is a conversion coating that is used on steels to improve corrosion resistance and minimize light reflection.

Powder Coated

This is a finish of applying powdered paint to the components and then baking it in an oven, which results in a stronger, more wear- and corrosion-resistant layer that is more durable than traditional painting methods.

Chromate Conversion Coating

Chromate conversion coating is used to improve the corrosion resistance of aluminum and aluminum alloys while keeping their conductive properties. It is also applied as a base layer prior to priming and painting parts

Plating

Include Nickel Plating, Silver Plating, Gold Plating, Zinc Plating, Chrome Plating, Tin Plating and etc, it is ideal to reduce corrosion, improve the appearance and function of solderability and electrical conductivity.

DLC (Diamond-Like Carbon) Coating

DLC (Diamond-Like Carbon) coating is a hard, wear-resistant coating made of a carbon-rich material that exhibits some of the properties of diamonds

Other surface finishes are also available. Learn more about our metal and plastic surface finishing capabilities here.

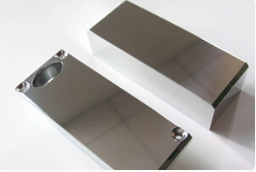

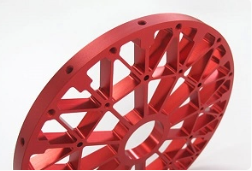

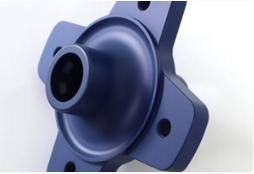

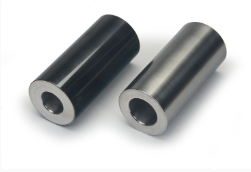

Gallery Of CNC Turning And Lathe Parts

We machine rapid prototypes and low & large-volume production orders for customers in multiple industries:

medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more.

Brass swiss screw maching service

SS304 SWISS LATHE MACHINED

AISI303 SWISS PRECISE PARTS AS MACHINED

AL5083 SWISS CNC MACHINED SMALL PARTS

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899