Electroplating Finishing Services

specializes in Electroplating finish services for your CNC parts, ensuring enhanced aesthetics, durability, and corrosion resistance. Expert precision for optimal component performance.

Electroplating Overview and Advantages

Electroplating, a metal finishing technique, deposits a thin metal layer onto an object’s surface using an electric current. Metal cations from a solution adhere to the object, forming a durable metal plating. This process not only enhances appearance but also provides corrosion resistance, reduces friction, and adjusts part thickness. Industries like jewelry, automotive, and electronics utilize electroplating to augment product properties and aesthetics.

Enhanced Appearance

Electroplating adds shine, luster, and

aesthetic appeal to objects, making

them attractive and visually pleasing

to users and consumers

Corrosion Resistance

By adding a protective layer, electroplating

prevents rusting and corrosion, extending

the lifespan of metal parts in various environments.

Increased Durability

he added metal layer provides wear

resistance, ensuring products withstand

regular usage and adverse conditions longer

than untreated counterparts.

Reduced Friction

Certain electroplated coatings,

like nickel, decrease friction

in moving parts, minimizing wear

and improving overall functionality

Improved Conductivity

Gold or silver electroplating can

enhance electrical conductivity,

vital for electronic components and

connectors for efficient performance.

Thickness Control

Electroplating allows precise

control over coating thickness,

catering to specific applications

and ensuring uniformity across parts

Types Of Electroplating

Nickel Plating

Nickel plating deposits a layer of nickel onto a substrate, offering a shiny finish that protects against corrosion and wear. Its versatility extends its applications from jewelry to machinery.

Features: Enhanced wear resistance, corrosion protection, bright appearance, and acts as an adhesive layer for subsequent coatings, especially in decorative uses.

Zinc Plating

By depositing a protective zinc layer onto ferrous metals, it primarily prevents rust, making it a staple in automotive components.

Features: Superior corrosion resistance, acts as a sacrificial layer (corroding before the substrate metal), and is a cost-effective rust prevention method for steel.

Chrome Plating

Recognized for its high-gloss, mirror-like finish, chrome is favored for decorative purposes and in industries where aesthetic appeal is paramount. It’s widely adopted for car parts, bathroom fixtures, and kitchenware.

Features: Brilliant shine, enhanced corrosion resistance, improved wear properties, and an impressive aesthetic boost, especially when applied over nickel.

Silver Plating

A method cherished both for its excellent electrical conductivity and its aesthetic allure. Often used in electrical components, silver plating ensures efficient signal transmission. It also finds its place in the world of jewelry, tableware, and musical instruments due to its captivating shine.

Features: Superior electrical conductivity, antimicrobial properties, solderability, and a radiant, reflective finish that offers elegance to decorative pieces and functionality in electronics.

Gold Plating

Renowned for its luster and resistance to tarnish, gold plating is a luxurious choice for both electronic components and jewelry. In electronics, it offers unmatched conductivity and corrosion resistance.

Features: Exceptional electrical conductivity, resistance to oxidation, aesthetic brilliance, and a touch of luxury to items, imparting both functionality and prestige.

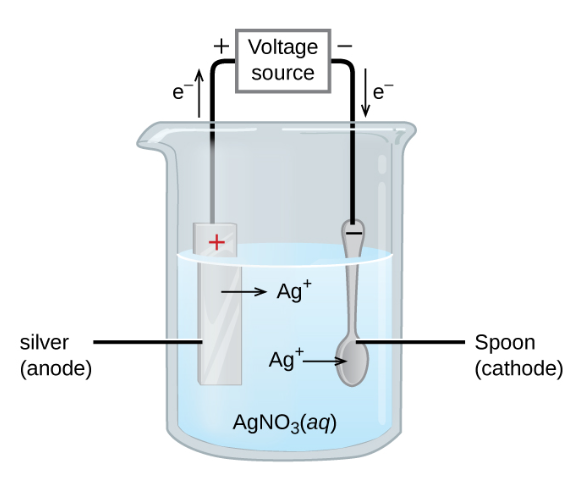

Common Process Of Electroplating

Preparation: The item (workpieces) is cleaned thoroughly to remove contaminants, oils, and oxides. This ensures a smooth and pure surface for efficient metal adhesion

Bath Setup: A bath containing the desired metal salt solution is prepared. The substrate becomes the cathode, while an electrode of the plating metal serves as the anode.

Electroplating: An electric current is applied, causing metal ions from the solution to reduce and deposit onto the substrate’s surface, forming a coherent metal layer.

Finishing and Inspection: If necessary, the plated item is rinsed, dried, and subjected to any post-plating treatments. Finally, it’s inspected for quality and adherence to specifications.

Other Finishing Services Available

Rust Our One-Stop Finishing Excellence

Metal Plating

Copper Plating Electroless Nickel Nickel Plating Nickel Sulfamate Tin Plating Zinc Plating

Anodizing type II (Glossy)

Anodizing type II (Matte)

Anodizing Type III Hard coat

Mechanical Polishing

Electropolishing

Vibratory Polishing

Mirror Polishing

Glass Bead Blasting

Ceramic Bead Blasting

Plastic Bead Blasting

Steel Shot Blasting

Stainless Steel Bead Blasting

Powder coating is a dry finishing process, using finely ground particles of pigment and resin electrostatically charged and sprayed onto surfaces. Cured under heat, it creates a durable, uniform, and attractive finish, popular for its environmental and performance benefits.

Black oxide, a conversion coating in surface finishing, chemically forms a protective black layer on metals, primarily ferrous alloys. It enhances corrosion resistance, reduces light reflection, and adds decorative appeal. Applied through hot or cold processes, the finish is often sealed with wax or oil to boost durability and protection.

Chromate Conversion Coating (Alodine/Chemfilm)

Chromate conversion coating, often known as Alodine or Chemfilm, is a surface treatment for aluminum and its alloys. It forms a thin, protective chromate layer, enhancing corrosion resistance, promoting paint adhesion, and providing electrical conductivity. Commonly used in aerospace and automotive industries, it offers a decorative finish with minimal dimensional change.

DLC (Diamond-Like Carbon) Coating

DLC (Diamond-Like Carbon) coating is a nanocomposite finish that imparts a hard, wear-resistant surface to materials. Mimicking properties of natural diamond, it offers exceptional lubricity, corrosion resistance, and a reduced friction coefficient, making it ideal for automotive, tools, and precision components.

Brushing in surface finishing uses abrasive brushes to create fine, consistent lines on metal surfaces. This mechanical process enhances appearance, masks defects, and prepares surfaces for coatings. Offering various textures, from short to long grains, brushing ensures aesthetic refinement for various applications.

Titanium anodizing is a surface finishing process that modifies the oxide layer on titanium components. Enhancing corrosion resistance and biocompatibility, it also adds vibrant, interference-based colors without dyes or pigments. Popular in medical devices and aerospace, it combines aesthetics with functional benefits

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899