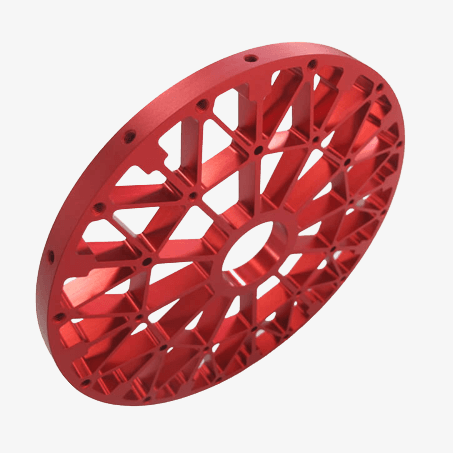

Powder Coating Finishing Services

Powder coating is a finishing process used to apply a protective or decorative layer on various materials, most commonly metal.

The technique employs a dry powder, typically composed of resins, pigments, and hardening agents, which is electrostatically applied to a surface and then cured under heat.

This creates a durable, corrosion-resistant, aesthetically pleasing and environmentally friendly coating compared to traditional liquid paints.

Powder Coating Overview and Advantages

Powder coating is a finishing process used to apply a protective or decorative layer on various materials, most commonly metal.

The technique employs a dry powder, typically composed of resins, pigments, and hardening agents, which is electrostatically applied to a surface and then cured under heat.

This creates a durable, corrosion-resistant, aesthetically pleasing and environmentally friendly coating compared to traditional liquid paints.

Durability

Environmentally Friendly

Cost-Effective

Aesthetic Versatility

Corrosion Resistance

Efficient Process

Types of Powder Coating Offered by AT-Machining

Epoxy

Known for its excellent corrosion resistance and toughness, epoxy powder coatings are generally used in indoor applications where UV resistance is not required. They are ideal for industrial and automotive underbody parts, electrical panels, and machinery.

Polyester

This type is the most widely used and is known for its good mechanical properties and durability. Polyester powder coatings offer excellent UV and weather resistance, making them suitable for outdoor applications like patio furniture, automotive exteriors, and fencing.

Polyurethane

Similar to polyester but with added flexibility, polyurethane coatings are useful for applications that require elasticity, chemical resistance, and a smooth finish. They are often applied to automotive parts and heavy-duty machinery.

Hybrid

These coatings are a combination of epoxy and polyester resins, aiming to offer good mechanical properties along with some level of UV resistance. They are typically used for indoor applications or those that do not require prolonged outdoor exposure.

Acrylic

Known for its clear and glossy finish, acrylic powder coatings are used when UV resistance and aesthetic appearance are important but extreme chemical or mechanical resistance is not necessary. They are commonly used in automotive clear coats and decorative items.

Textured

These specialized coatings create a textured finish, such as wrinkles, hammer tones, or matte finishes. They are used to enhance grip, hide surface imperfections, or simply for aesthetic reasons.

Does Powder Coating Affect CNC Parts Accuracy?

Powder coating does add some thickness to the part, which could affect tolerances if the coating is especially thick. Typical powder coatings add 50-75 microns of thickness.

The baking process for curing powder coated parts can cause some slight warping or distortion, especially on larger or thinner parts. Preheating parts prior to coating can minimize this.

Masking and plugging any machined holes, bores, threads etc prior to coating is advisable to avoid affecting tolerances. The coating buildup could cause issues otherwise.

Powder coating over sharp edges or corners can round them off slightly, again affecting critical tolerances. Masking these areas can prevent this.

In general, any precision-machined surface that requires tight tolerances should be masked if possible prior to powder coating to avoid the coating affecting dimensions.

For most commercial precision, powder coating does not affect tolerances significantly as long as proper masking and curing procedures are followed. But for ultra-high precision work, coatings should be avoided if possible.

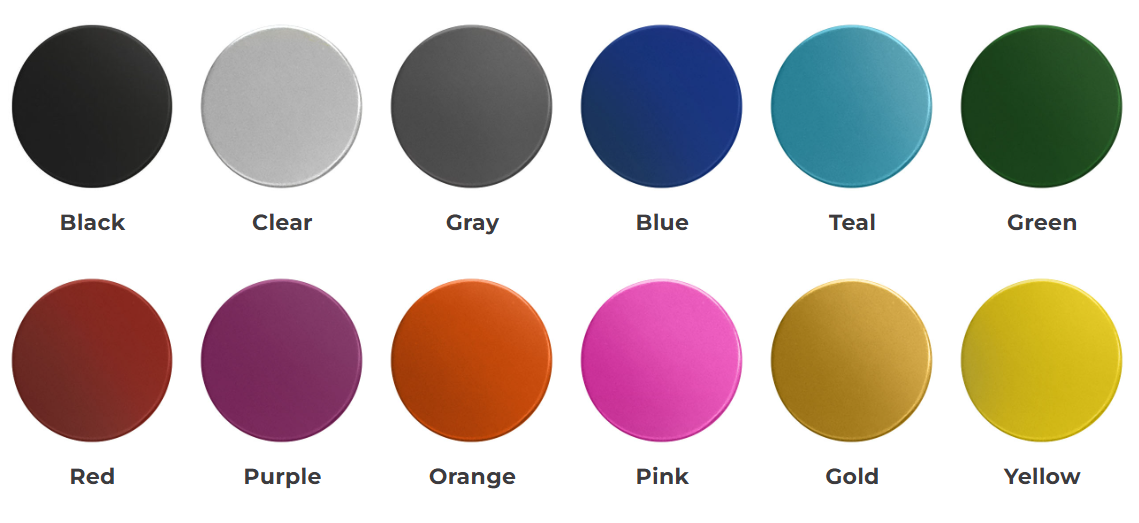

Color options for Powder Coating

Powder coating offers extensive color options, including various RAL codes for precise matching. Different levels of gloss, from matte to high-gloss, can also be achieved, providing versatile aesthetic outcomes.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899