Automotive Prototyping Services Auto Parts Manufacturing

we excels in automotive prototyping, delivering exceptional precision in auto parts manufacturing. Specializing in crafting high-quality mechanical components, our expertise ensures top-tier results in every project

Importance of Automotive Prototyping

Automotive prototyping plays an invaluable role in the product development process within the automobile industry.

It allows manufacturers to visualize, test, and refine design concepts, ensuring the produced vehicle parts are high-performing and safe before mass production.

Moreover, prototyping can reveal unforeseen issues at an early stage, thus preventing costly errors down the line. Prototypes also serve as an effective tool for communication among teams and stakeholders, helping to align everyone with the product vision.

In summary, automotive prototyping significantly reduces the risks associated with large-scale production, paving the way for manufacturing excellence and higher customer satisfaction.

Automotive prototype manufacturing is intrinsic to all stages of design and development, encompassing concept proofing, CAD model visualization, structural and performance verification, functional and engineering tests, and crucially, validating manufacturing processes. In essence, it’s a comprehensive tool for ensuring product integrity and production efficacy.

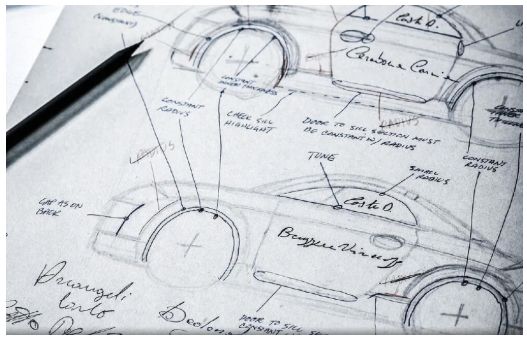

CAD Model of Prototype Creation

The CAD Model Creation in automotive prototyping employs cutting-edge software to fashion a precise, three-dimensional representation of the vehicle design. This model enables engineers to scrutinize every detail, experiment with alterations, simulate real-world driving conditions, and optimize parts — all preceding the production of a physical prototype, ensuring efficiency and accuracy

Functional and Engineering Testing

Functional and Engineering Testing of an automotive prototype involves evaluating the car’s mechanical systems, electronics, and overall functionality. This phase tests the vehicle’s engine performance, drivetrain efficiency, electrical systems, and software integration. Engineers assess reliability, safety features, and user interface functionality, ensuring all components work harmoniously under real-world conditions. This process is crucial for identifying and rectifying any issues before final production.

Production Process Validation

Production Process Validation of an automotive prototype focuses on verifying the manufacturing process’s efficiency and quality. It entails producing a prototype using the intended production line and equipment to ensure that mass production is feasible, consistent, and meets quality standards. This stage tests assembly methods, tooling accuracy, and production timing, crucial for identifying potential issues in the manufacturing workflow before full-scale production commences.

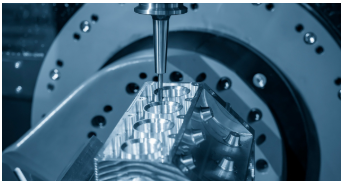

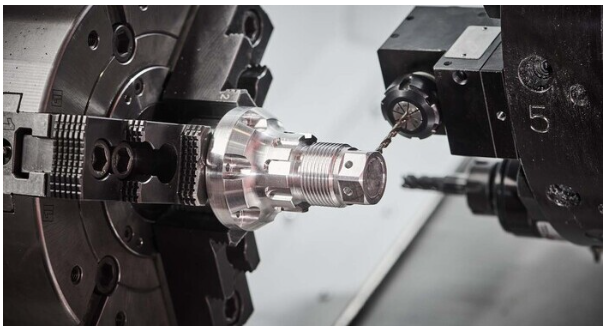

CNC Machining

CNC Machining shapes precise automotive prototypes with high accuracy and repeatability.

Vacuum Casting

Vacuum Casting creates precise, high-quality automotive prototypes quickly and cost-effectively.

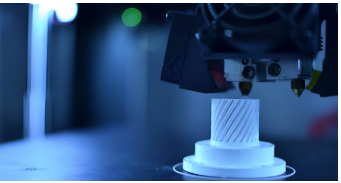

3D Printing

3D Printing crafts detailed automotive prototypes efficiently and with high precision.

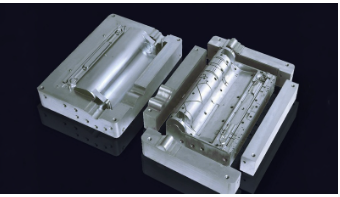

Prototype Tooling

Prototype Tooling

Rapid Injection Molding

Rapid Injection Molding quickly produces plastic parts using pressurized mold cavities.

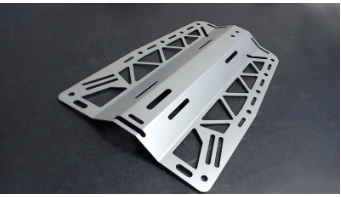

Sheet Metal Fabrication

shaping, cutting, and assembling metal into desired structures.

Precision Automotive Mechanical Components

We expertly crafts precise, functional automotive mechanical prototypes using CNC machining, silicone molding, and rapid tooling. This precision approach provides accurate performance feedback and data in challenging tests, crucial for design validation and refinement.

Custom car parts for your unique prototype design

We aids in creating custom car parts for unique prototype designs using advanced techniques like CNC Machining and Vacuum Casting. These methods allow for high precision and versatility in producing components that meet specific design requirements, ensuring a perfect fit and function for your custom automotive prototypes.

CNC Machining offers detailed and accurate fabrication, while Vacuum Casting is ideal for replicating parts with consistent quality, making AT-Machining a reliable partner for custom automotive prototyping needs.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899