Precision 5-Axis CNC Machining

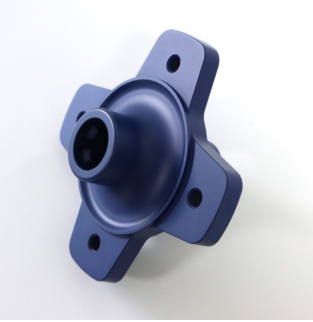

Secure intricate parts via our 5-axis CNC machining. High precision, complex geometries, competitive pricing, and swift delivery assured.

What Is 5-Axis CNC Machining?

5-axis CNC machining is a groundbreaking method in manufacturing that allows for the creation of exact and complex parts. This technology uses computer numerical control (CNC) to simultaneously direct machine tools along five axes. This multi-directional approach enables the machining of complex shapes and designs that would be virtually impossible using traditional manufacturing methods.

Unlike 3 or 4-axis machining, which are confined to movements on X, Y, Z planes and one-axis rotation, 5-axis CNC machining adds two more rotational directions. This means the machine can move left/right, up/down, forward/backward, and even rotate around the X and Y axes all at once, providing more flexibility and precision by reaching the workpiece from any angle. 5-axis CNC machining is a sophisticated technology that delivers unparalleled precision, complex geometries, and a competitive edge to businesses across a multitude of industries.

Advantages Of 5-Axis CNC Machining

| High Precision | With 5-axis CNC machining, You can receive parts made with extreme precision. The technology can handle intricate designs with a tolerance of up to ±0.005mm, ensuring high-quality results for your complex projects. |

| Incredible Flexibility | 5-axis CNC machining allows us to make uniquely shaped parts that other methods can’t. This gives you more design and function options for your product. |

| Efficient Process | The one-setup process of 5-axis CNC machining means your parts can be completed faster and with fewer potential errors. This efficiency can shorten production schedules and reduce the time-to-market of your products. |

| Speedy Production | With reduced lead times, You can respond swiftly to market demands and maintain a competitive edge. Whether meeting a tight schedule or scaling up production quickly, 5-axis CNC machining is up to the task. |

| Cost Savings | Despite a higher initial cost, the long-term benefits of 5-axis CNC machining can lead to significant cost savings. Fewer setups, reduced waste, and quicker delivery all contribute to a more economical production process. |

Comparative Analysis Of 3-Axis, 4-Axis, And 5-Axis CNC Machining Features

| Feathure | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

| Degrees of Freedom | Moves in X, Y, Z axes | Adds rotation around X or Y axis | Adds rotation around X or Y axis |

| Complexity of Shapes | Limited to geometric shapes | Can create more complex shapes | Can create highly complex shapes |

| Setup Times | Multiple setups may be needed for complex parts | Usually less than 3-axis as one more side of a part can be machined | Single setup due to simultaneous multi-axis movement, saves time |

| Surface Finish | Good, depends on setups | Better, due to less setups | Best, continuous tool-path movement, less scalloping |

| Tool Access & Collision | Potential limitations due to tool geometry | Improved access over 3-axis | Best access and collision avoidance |

| Cost | Lowest among the three due to simpler mechanics | Moderately higher due to additional axis | Highest, due to complex mechanics and software |

Materials For 5-Axis CNC Machining

Aluminum

Aluminum is lightweight, with good strength-to-weight ratio, excellent machinability, and thermal conductivity. It's cost-effective and easily recyclable. However, in CNC machining, aluminum's softness can cause tooling issues, and its thermal conductivity may necessitate careful heat management. It also has lower tensile strength compared to some other metals.

Stainless Steel

Stainless steel is robust, corrosion-resistant, and has high tensile strength, making it suitable for demanding applications. It withstands high temperatures well. In CNC machining, however, it's harder and more abrasive, which can lead to faster tool wear. Moreover, stainless steel's work hardening properties require careful feed rates and cutting speeds.

Alloy Steel

Alloy steel, noted for its strength and toughness, offers wear resistance and varied hardness based on alloying elements. It's adaptable for diverse applications. However, in CNC machining, its hard nature can stress tools and machining processes, necessitating careful planning. Its diversity in composition can also complicate consistent machining performance.

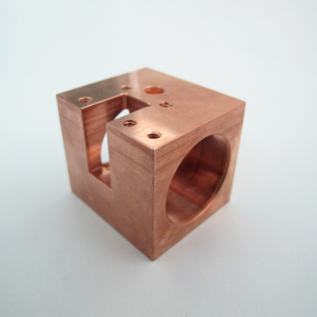

Copper

Copper is highly conductive, both thermally and electrically, with good corrosion resistance, making it ideal for electrical components. However, its softness and malleability can cause difficulties in CNC machining. Copper often causes tool wear, has a tendency to stick to cutting tools, and requires slower feed rates.

Brass

Brass is a corrosion-resistant alloy with good thermal conductivity and aesthetic appeal. In CNC machining, brass is desirable for its easy machinability, making it a cost-effective choice for intricate designs. However, its lower strength and hardness compared to steel limit its usage in high-stress applications.

Titanium

Titanium offers high strength, light weight, and exceptional corrosion resistance, ideal for aerospace and medical applications. However, in CNC machining, its hard nature leads to rapid tool wear, and its low thermal conductivity can cause heat concentration, requiring careful control of machining parameters and coolant usage.

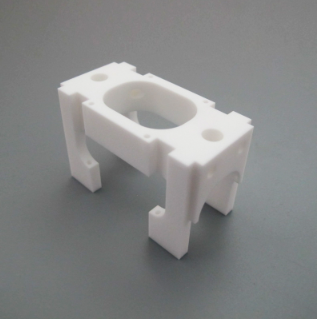

POM

POM, or polyoxymethylene, is known for high stiffness, low friction, and excellent dimensional stability, making it suitable for precision parts. In CNC machining, POM is easy to machine but tends to generate chips and requires proper ventilation due to potentially harmful fumes. It's also less heat-resistant than some other plastics.

PEEK

PEEK, or polyether ether ketone, is a high-performance plastic known for its high temperature resistance, excellent mechanical properties, and chemical resistance. However, in CNC machining, PEEK's hard and abrasive nature can cause tool wear. It requires precise machining parameters and may be more costly compared to other plastics.

Ceramic

Ceramics are hard, heat-resistant, and offer electrical insulation, making them suitable for many applications. However, in CNC machining, their extreme hardness and brittleness can cause tool wear and present difficulties in maintaining precision. Special machining techniques, such as grinding, are often required, increasing cost and complexity.

Why Choose PY-precision as your partner

Extensive Expertise

PY-precision boasts an assortment of 5-axis CNC machinery and techniques. Our team of engineers can suggest the most suitable 5-axis CNC machining solutions tailored to your financial constraints.

Precision & Flexibility

Our manufacturing unit is designed for optimal efficiency, reducing material waste and ensuring speedy yet accurate results. PY-precision is capable of maintaining a stringent tolerance of +/-0.002mm for components with intricate shapes.

One-Stop Solution

Our CNC operations are hosted in a contemporary facility, equipped with more than 50 top-tier 5-axis CNC machines. PY precision is proficient in undertaking the most intricate CNC machining parts customization, delivering results in as swift as 5 days.

Quality & Refund Assurance

Our thorough evaluation and testing ensure that you consistently receive flawless components. Nonetheless, should there be any discovered defect, we are committed to either refunding or redoing your order.

Saving Your Cost

Through diligent efforts across all processing aspects, our engineering team's strategies can precisely curtail your costs, achieving a reduction between 30%-50%.

Material Expert

PY-precison is not only specialized in machining technology, but we are also dedicated to research and experimentation with new materials, becoming a material specialist in the CNC machining industry.

For the 3D drawing, we would prefer STEP, IGES, or X_T format.For the 2D drawing, we would prefer PDF format there are tolerances with the dimensions if possible.

Py-precision accepts payment in two ways: 1. Bank to bank wire transfer

2. PayPal

CNC Precision Machining Tolerances down to ±.0002″ (0.005mm).

PY can manufacture and inspect to tight tolerances per your drawing specifications.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899